Titanium 3D printing

Amnovis’ founders were among the first to 3D print titanium medical devices, such as orthopedic and spinal implants. Today, they are using their experience and expertise to even further advance the technology and potential applications for titanium 3D printing.

Ti-6Al-4V Grade 23 vs. Ti Grade 1

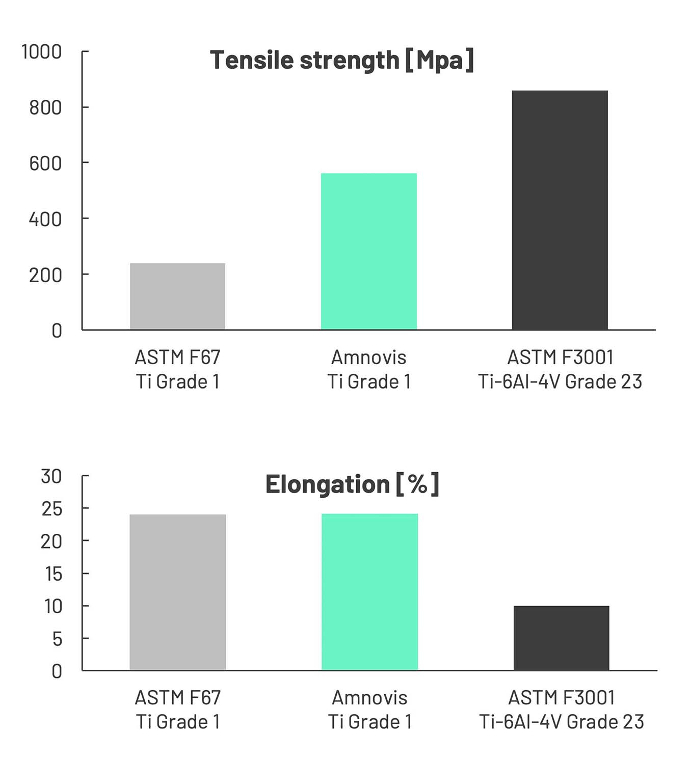

Titanium 3D printing usually means Laser Powder Bed Fusion (L-PBF) of Ti-6Al-4V Grade 5 or Grade 23. Despite the lower strength, Ti Grade 1 pure titanium (CP Ti) has some interesting properties that can be beneficial for certain applications, when it is 3D printed. Amnovis has validated both Ti-6Al-4V Grade 23 and Ti Grade 1 to meet industry-accepted standards.

Amnovis CP Ti

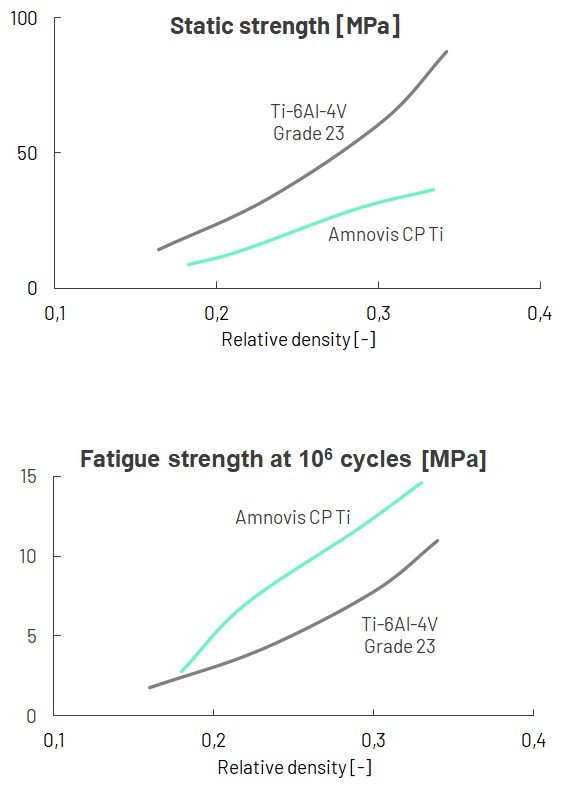

The bulk properties of the Amnovis CP Ti exhibit a unique combination of high strength and high ductility, and lattice structures even outperform identical Ti-6Al-4V Grade 23 structures in fatigue strength. Combining all these benefits, Amnovis CP Ti is an interesting alternative for Ti-6Al-4V Grade 23, and opens up a lot more applications for 3D printed titanium.

Eliminating heat treatment

Thanks to the in-house developed and proprietary process for Ti Grade 1 (we call it the Amnovis CP Ti), Amnovis is able to meet and exceed the requirements of the corresponding ASTM standard, while eliminating heat treatment after printing. What's in it for you? Premium quality titanium parts at reduced cost and lead times!

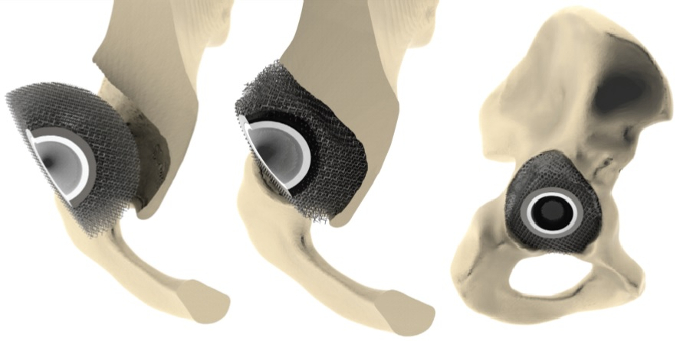

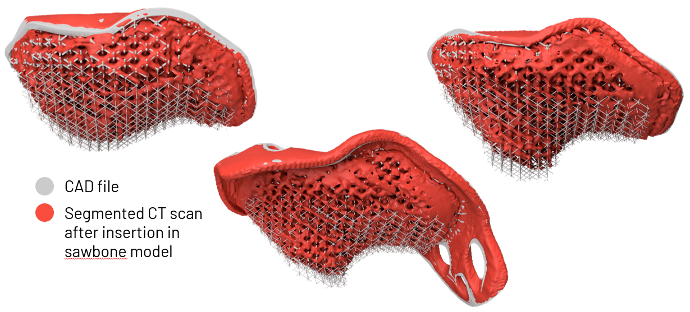

Deformable implants

The use of 3D printed patient-specific implants is limited due to the high costs. What if you could have a patient-specific implant at the cost of a standard component? Amnovis has developed a platform technology to manufacture off-the-shelve implants with an oversized lattice structure, that can be deformed according to the patient's anatomy.

Typical properties and applications

Ti-6Al-4V Grade 23

- Validated to ASTM F3001 and included in our FDA Master File

- High strength, medium ductility

- Alloying components

- Not deformable

Ti Grade 1 (CP Ti)

- Validated to ASTM F67 and included in our FDA Master File

- Medium strength, high ductility

- No alloying components

- Deformable

Application examples

Ti-6Al-4V Grade 23 spinal interbody fusion cages

Ti Grade 1 bone plates

Eliminating heat treatment

Most 3D printed titanium implants are made of Ti-6Al-4V Grade 23 and need a special heat treatment to achieve the required mechanical properties. As this is considered a special process, it complicates process and product validation and adds significantly to the total cost and lead time of 3D printed titanium implants.

Amnovis has validated a 3D printed titanium with high strength and ductility without the need for a heat treatment, reducing costs and lead times for innovative implants: meet the Amnovis CP Ti.

Reduced cost

Save on expensive and outsourced heat treatments.

Shorter lead times

Faster product development and qualifications and shorter time to market.

Premium quality

High strength, high ductility titanium with no alloying components.

Customers rely on us for 3D printed titanium implants.

Contact us to find out how you can benefit from this material innovation.

Amnovis CP Ti

Amnovis has developed and validated a proprietary process of a commercially pure titanium (CP Ti) that combines the chemical purity and ductility of CP Ti Grade 1 with high tensile strength. Today it is already used by several of Amnovis' customers for orthopaedic and spinal implants worldwide. Through our FDA Master File, you can leverage the unique capabilities of this material to bring new products to the US market with a simplified regulatory pathway.

Bulk material

Chemical properties

-

- Chemical purity of CP Ti Grade 1

-

- No alloying components

Static mechanical properties

-

- Elongation > 24 %

-

- Strength close to CP Ti Grade 4

-

- Results based on 350+ tensile tests and ANOVA + six sigma tolerance intervals

Dynamic mechanical properties

-

- Fatigue strength of > 240 MPa after 107 cycles

Lattice structures

Static mechanical properties

-

- Ti-6Al-4V Grade 23 is still the strongest material (like the bulk material properties)

-

- Ti-6Al-4V Grade 23 shows brittle fracture while the Amnovis CP Ti shows ductile deformation

Dynamic mechanical properties

-

- Amnovis CP Ti lattice structures outperform identical Ti-6Al-4V Grade 23 structures when dynamically loaded

Deformable implants

Source: Magré, Master Thesis, Delft University of Technology, 2020

Mass produced, malleable shape

The proprietary and patented concept of the deformable implants (Patent No. 12,144,736) relies on the unique properties of the Amnovis CP Ti and its high ductility. Highly porous lattice structures are printed in an oversized volume that allows to be deformed according to the patient's anatomy. This can be done either pre- or intraoperatively.

Benefits

-

- Produced in standard, oversized, shapes at the cost of serial manufactured products

-

- Deformable according to the anatomy of each individual patient

-

- Deformation behavior can be tailored to the application

Application examples

-

- Acetabular hip cups or acetabular reconstruction implants

-

- Bone filler materials

-

- Dental implants

-

- Spinal implants

Develop next generation orthopaedic implants.

Join forces with us to bring this innovation to the market